The Past, Present, and Future of Metal Prices: Impact on the Bearing and Bushing Industry

The Past, Present, and Future of Metal Prices: Impact on Bearings and Bushings Industry

Metals like bronze, brass, aluminum, and iron-copper alloys are the foundation of many industrial components, especially bearings and bushings. These materials provide the essential mechanical properties needed for precision components used across industries such as automotive, aerospace, heavy equipment, and energy. Fluctuations in metal prices directly influence the cost, design, and availability of bearings, which impacts companies like Bunting Bearings. This article explores the historical evolution of metal prices, analyzes current market conditions, and forecasts future trends, with a particular focus on metals crucial to the bearing and bushing industries.

A Historical Overview: Metal Prices and Bearings/Bushings

Historically, the prices of metals have experienced substantial fluctuations, largely driven by global economic cycles, industrial revolutions, and technological advancements. For instance:

- Bronze, a key material for bushings and bearings, has been in demand since the Bronze Age due to its anti-corrosive properties and high wear resistance. However, the reliance on copper, a component of bronze, means the price of bronze has mirrored copper price trends.

- The mid-20th century industrial boom saw prices of industrial metals surge due to increased infrastructure projects and manufacturing demands. The rise of the electrical industry created sustained demand for copper, essential for power grids and electrical motors.

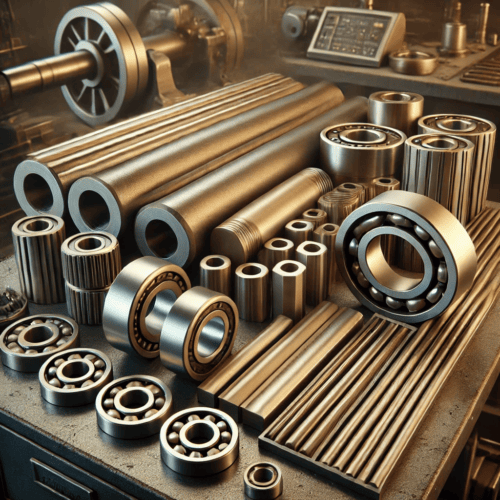

- Powdered metals emerged as an innovative manufacturing process during the 20th century, enabling efficient production of self-lubricating bearings. Companies like Bunting Bearings capitalized on this by producing SAE 841 bronze and SAE 863 iron-copper bars, optimized for low-friction, high-durability applications

The Current State of Metal Prices: A Market in Flux

The pricing of metals such as bronze, aluminum, and copper remains highly dynamic. Several key factors shape the current metal market:

Global Supply Chain Disruptions and Inflation

- The COVID-19 pandemic caused major disruptions in mining operations and transportation, leading to reduced metal supply.

- Geopolitical conflicts, such as the Russia-Ukraine war, affected the supply of critical industrial metals like aluminum, causing market volatility

Growing Demand from Green Energy Sectors

- Copper and aluminum are in high demand for their use in electric vehicles (EVs) and renewable energy infrastructure. Bearings used in wind turbines and EV motors rely heavily on these materials.

- Companies such as Bunting Bearings have responded by promoting eco-friendly alloys like ECO Bronze, which is lead-free and complies with environmental regulations

Market Impact on Bearings and Bushings

The bearing and bushing industries must manage price fluctuations effectively to avoid disruptions in production. Materials like SAE 841 sintered bronze and iron-copper bars (SAE 863) remain vital for products where self-lubrication and high-temperature resistance are required. Companies like Bunting Bearings offer a variety of customized alloys and powdered metal components to meet these demands.

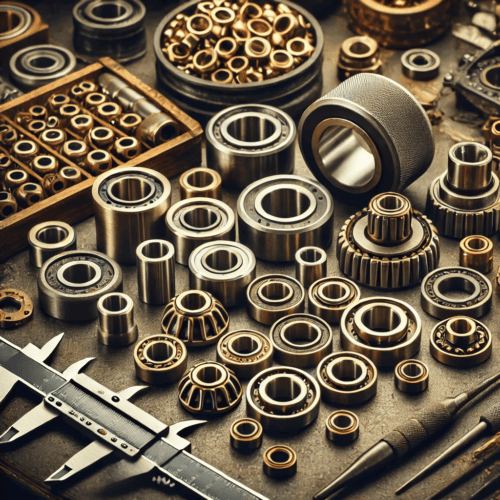

Key Metals in the Bearings and Bushings Industry

Several metals and alloys play an essential role in bearing and bushing manufacturing. Understanding the properties and market trends of these metals is crucial for companies in the industry:

Bronze Alloys

- SAE 841 Bronze: Widely used in bearings for its excellent self-lubricating properties, this alloy is oil-impregnated, offering long-lasting performance in applications with varying temperatures.

- ECO Bronze: This lead-free alternative to traditional bronze alloys, introduced by Bunting Bearings, is environmentally sustainable and suitable for applications that require reduced environmental impact.

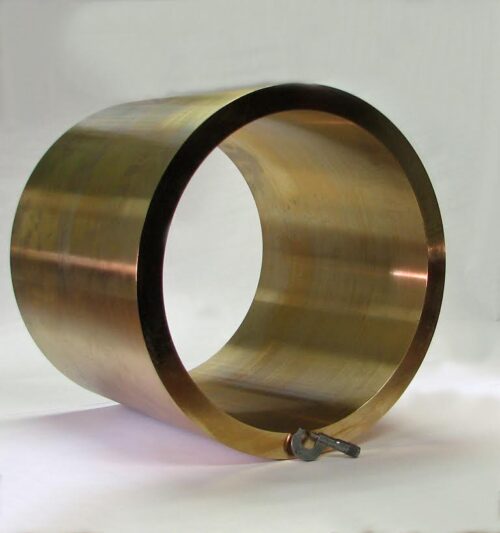

Iron-Copper Composites (SAE 863)

- Iron-copper alloys, known for their strength and wear resistance, are employed in heavy-duty applications. These materials are ideal for machinery operating under high loads and extreme conditions.

Aluminum and Powdered Metals

- Aluminum: While not as common as bronze, aluminum housings are used for bearing assemblies to reduce weight. Aluminum’s corrosion resistance makes it suitable for marine and aerospace applications.

- Powdered Metals: The powdered metal process allows manufacturers to create components with complex geometries and excellent performance at reduced costs. This technology plays a crucial role in the production of sleeve bearings and other precision components.

Future Trends in Metal Prices and Their Impact on Bearings

Several emerging trends will shape the future of metal prices, influencing the bearing and bushing industries.

Decarbonization and Sustainability Initiatives

- Governments are tightening regulations on the use of lead and other hazardous materials, leading to increased demand for alloys like ECO Bronze.

- Recycling and circular economy initiatives will further influence the prices and availability of metals, as manufacturers seek sustainable sourcing strategies.

Technological Innovation in Manufacturing

- 3D printing and additive manufacturing offer new ways to produce metal components with minimal waste, potentially reducing the demand for raw materials.

- Advances in powdered metal technologies will enable companies like Bunting Bearings to enhance the performance of their products while controlling costs.

Continued Market Volatility

- Ongoing geopolitical conflicts and trade tensions could continue to disrupt metal supplies, leading to unpredictable price changes.

- The electric vehicle boom and increasing investments in renewable energy infrastructure will maintain high demand for copper and aluminum, potentially driving prices up in the short term.

Strategies for Navigating Metal Price Fluctuations

Companies in the bearing and bushing industries must adopt strategies to mitigate the risks associated with volatile metal prices.

- Diversifying Supply Chains: Establishing partnerships with multiple suppliers ensures a steady supply of critical materials.

- Adopting Sustainable Practices: Using eco-friendly alloys and promoting recycling efforts can reduce exposure to price swings.

- Investing in R&D: Innovations in manufacturing processes, such as Lube-Align bearings, offer operational efficiencies and long-term cost savings.

The Role of Companies Like Bunting Bearings

Companies such as Bunting Bearings play a pivotal role in providing solutions that address both performance and sustainability challenges. Their extensive range of products, including powdered metal bars and self-lubricating bushings, demonstrates the importance of material innovation in a competitive market.

Similarly, our friends over at Bushings and Bars specialize in customized metal components, ensuring that clients receive the most appropriate solutions for their specific needs. Both companies highlight the importance of proactive strategies to manage metal price fluctuations, ensuring continuity and quality for their customers.

The bearing and bushing industries operate within a dynamic environment where metal prices play a crucial role. From the historical evolution of bronze and powdered metals to the current challenges posed by market volatility and supply chain disruptions, understanding these trends is essential for industry players. Companies like Bunting Bearings are well-positioned to navigate these challenges by leveraging innovation, sustainability, and strategic partnerships.

Looking ahead, the focus on green materials and advanced manufacturing technologies will continue to shape the future of the industry. By staying ahead of these trends, businesses can ensure long-term success while meeting the evolving needs of their customers.

For more detailed information on specific products and innovations, visit Bunting Bearings.