Bunting Bearings Completes Casting Plant Expansion

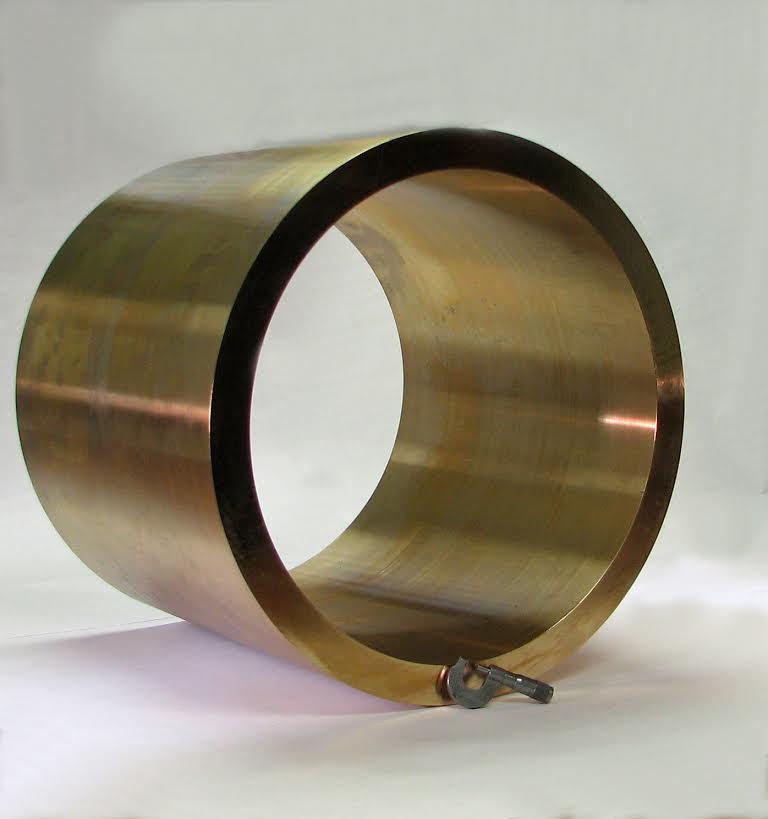

Bunting Bearings recently completed a large expansion to our Delta, OH, centrifugal casting plant. Centrifugal casting is one of our main specialties, and our customers value our ability to create high-value, cost-effective centrifugal castings that can be machined to a finished product. With this new expansion, we’re excited to further expand on our abilities to provide the highest quality casting services to our clients.

Here’s an overview of our casting plant expansion and how it will benefit our capabilities moving forward:

Our Casting Plant Expansion

We invested in an extension to our plant to bring new value to our customers. With our new plant, we can now produce longer and larger centrifugal castings with lead times of 2–4 weeks and expedited delivery times of 48–72 hours.

We also dedicated new resources to our machine shop in Holland, OH. We installed five new live tooling machining centers as well as a vertical turret lathe to handle larger longer centrifugal castings.

New Casting Specifications

Our new equipment has enabled us to produce larger casting volumes at optimal efficiency. With our expanded capabilities, we can:

- Pour vertical castings with a size range of 3” up to 36” outside diameter as well as horizontal castings of 27” diameter and 60” length

- Achieve tighter grain structures, leading to improved physical properties

- Fill low-, medium-, and high-volume orders

- Perform QC testing at our in-house laboratory to ASTM B271– and ASTM B22.

Full Casting Solutions at Bunting Bearings

We at Bunting Bearings continuously seek new ways to best satisfy our customers’ needs. Investing more in our facilities and equipment is one such way for us to achieve this goal, and we’re pleased to expand our casting offerings to cover an even greater span of casting size requirements.

Bunting Bearings is a leading manufacturer of high-performance, environmentally friendly bearings and cast materials. Our products include a wide variety of lead-free products made from top-quality polymers and bronze. To learn more about centrifugal castings or our other capabilities and services, contact us today.